Tel: +39.0444.887141

Noventa Vicentina

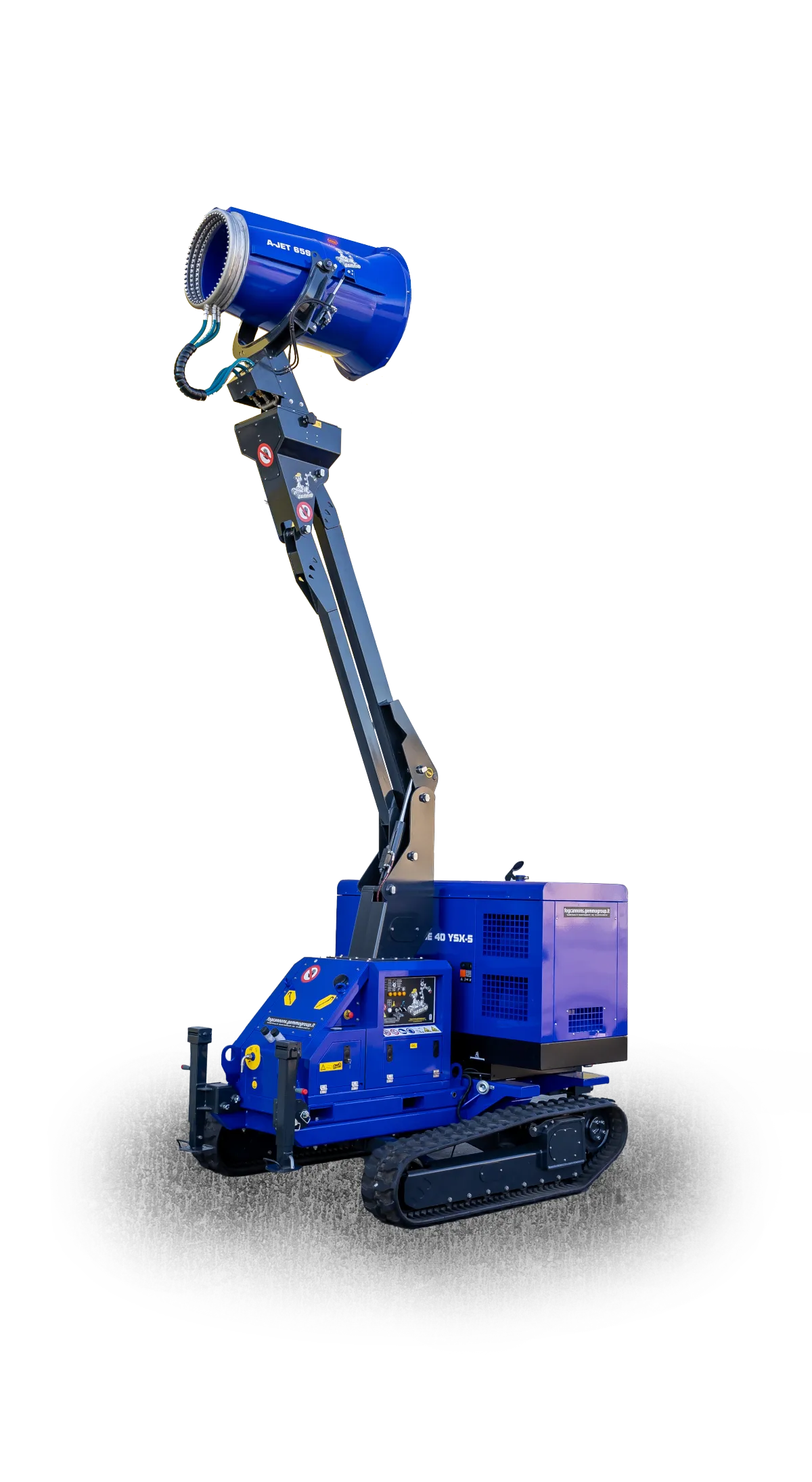

A-JET65S BACKPACK

SOLD OUT

Next Batch Coming Soon

Want to be the first to know when the next batch is available?

Leave your details and we’ll contact you as soon as new units are ready for delivery.

In high-emission contexts such as waste collection centers, quarries or industrial plants, dust control is not optional. It's a priority.

The A‑JET65S BACKPACK Fog Cannon is designed to meet this need with solid, reliable technology built for intensive, continuous operation.

Key strengths:

Coverage of up to 13,300 m² with automatic 360° rotation

Crawler-mounted frame with integrated hydraulic movements — ideal for rough terrain

Remote control up to 200 meters, ensuring safety and workflow efficiency

See the A-JET65S in Action

Health Risks

Inhaling fine dust particles, such as those from cement or crystalline silica, can cause:

Allergies and Irritations: Dust can trigger rhinitis, asthma, and other allergic reactions, compromising the well-being of workers.

Chronic Respiratory Diseases: Prolonged exposure can lead to chronic obstructive pulmonary diseases, reducing workers' respiratory capacity.

Silicosis: An irreversible lung disease caused by inhaling silica dust, commonly found on construction sites.

Legal and Regulatory Consequences

In Italy, dust management on construction sites is regulated by the Consolidated Law on Occupational Safety (Legislative Decree 81/2008). Non-compliance with these regulations may result in:

Administrative Sanctions: Significant fines for non-compliance with safety regulations.

Work Suspension: Authorities may mandate an immediate halt to site operations until the worksite is brought into compliance.

Criminal Liability:

In the event of harm to the health of workers or nearby residents, those responsible may be subject to criminal prosecution.

All units from this batch have been sold out.

New A‑JET65S BACKPACK Fog Cannons will be available soon, and only those who register now will receive priority notification.

Want to be among the first to know when the next A‑JET65S BACKPACK units are ready for your site?

Click below and complete the form with:

Company name

Email

It is already successfully used on dozens of worksites to reduce dust and improve safety.

Key Features of A‑JET65S

Key Features of A‑JET65S

1. Extended Throw Range:

A-JET 35S: Up to 35 meters of coverage with a treated surface of approximately 3,800 m².A-JET 65S: Up to 65 meters of coverage with a treated surface of approximately 13,300 m².

Ideal for covering different sizes of construction sites, from compact urban areas to large works.

2. Fine and targeted nebulization:

It produces a mist composed of micro-droplets (small size), which effectively bind to dust particles, breaking them down before they disperse.

3. energy efficiency:

400 V power supply and optimized energy consumption: A-JET 35S: 4-6 kW.A-JET 65S: 11-15 kW. Low consumption to ensure operational sustainability.

4. versatile configuration modes:

Available on trolley, fixed column, telescopic arm or even vehicle mounted.

5. silent technology:

Designed to reduce noise, making the gun particularly suitable for sensitive urban environments.

6. eco-friendliness:

Optimized water consumption thanks to fine atomization, reducing waste of resources.

7. made according to the principles of supply chain 5.0:

A production process that integrates advanced technology, environmental sustainability and human centrality to guarantee quality, efficiency and respect for the planet.

Benefits for Shipyards

1. health and safety of workers

Reduces the inhalation of harmful dust such as crystalline silica, cement and asbestos.

2. regulatory compliance

Helps comply with the provisions of Legislative Decree 81/2008 (Consolidated Law on Workplace Safety) regarding exposure to hazardous substances. Prevents fines and legal sanctions, protecting the company from possible lawsuits or suspensions.

3. improving environmental impact

It reduces air pollution caused by fine dust, respecting the environmental regulations in force. It improves the relationship with local communities, often sensitive to dust and noise problems.

4. greater reputation and reliability

Demonstrates the company’s commitment to health, safety and the environment, strengthening its reputation. Provides a competitive advantage in tenders, where compliance is often a key criterion.

5. operational efficiency

Avoid work interruptions due to reports or interventions by authorities.

6. reduction of operating costs

Optimized energy and water consumption guarantee significant savings.

7. versatile applications

Usable in different phases of the construction site: demolition, earth moving, material transport and reclamation. Adaptable to different contexts, from urban construction sites to large infrastructure works.

Benefits for Shipyards

1. health and safety of workers

Reduces the inhalation of harmful dust such as crystalline silica, cement and asbestos.

2. regulatory compliance

Helps comply with the provisions of Legislative Decree 81/2008 (Consolidated Law on Workplace Safety) regarding exposure to hazardous substances. Prevents fines and legal sanctions, protecting the company from possible lawsuits or suspensions.

3. improving environmental impact

It reduces air pollution caused by fine dust, respecting the environmental regulations in force. It improves the relationship with local communities, often sensitive to dust and noise problems.

4. greater reputation and reliability

Demonstrates the company’s commitment to health, safety and the environment, strengthening its reputation. Provides a competitive advantage in tenders, where compliance is often a key criterion.

5. operational efficiency

Avoid work interruptions due to reports or interventions by authorities.

6. reduction of operating costs

Optimized energy and water consumption guarantee significant savings.

7. versatile applications

Usable in different phases of the construction site: demolition, earth moving, material transport and reclamation. Adaptable to different contexts, from urban construction sites to large infrastructure works.

Current units have sold out.

Register now to be among the first to access the next batch of high-performance A‑JET65S BACKPACK Fog Cannons.

© Gemmo Group Srl | via Della Tecnica 34 | 36025 Noventa Vicentina (VI) Italy

Tel: +39.0444.887141 | P.IVA: 02963740242 | E-mail: [email protected] | PEC: [email protected]